Base Materials for PWBs

Thin Prepreg with Superior Surface Smoothness – GH-100 (Type DF), GH-200 (Type DF)

Product Information and Application

Content Goes Here

- Content Goes Here

Content Goes Here

- Content Goes Here

Features

- GH-100 (Type DF) and GH-200 (Type DF) have hybrid properties of package and high speed materials.

- Good for impedance control as thickness variation is small after press.

- Halogen free material with low CTE values in X, Y directions (α1, α2).

- Good dielectric properties by applying low dielectric glass cloths.

Characteristics

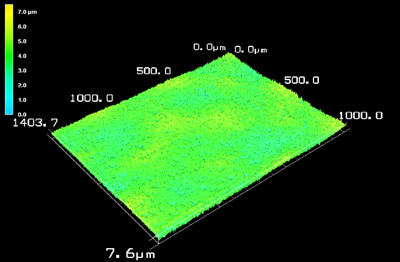

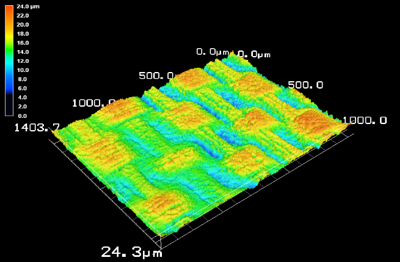

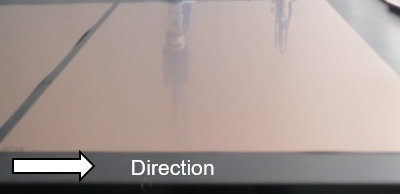

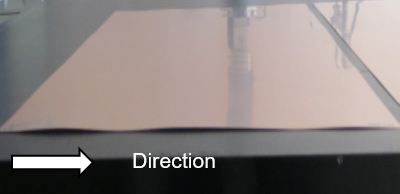

Surface Smoothness of Prepreg (Microscope)

(Type F)

Conventional

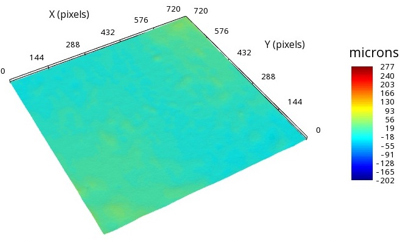

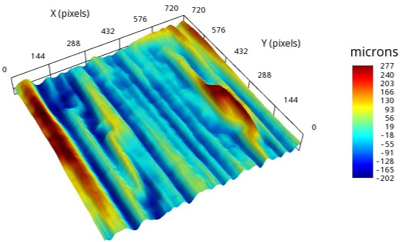

Panel Warpage of Prepreg after press (w/o copper, by shadow moire)

(Type F)

Conventional

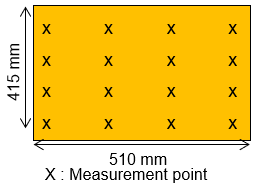

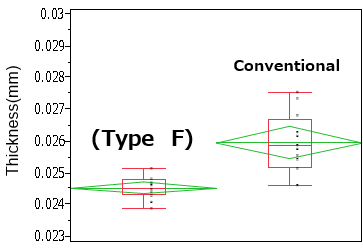

Prepreg thickness after Press

Laminate Condition

-

- GEA-705G1010F78

- Copper foil: 3 µm

- Laminate condition

- Temp.: 230℃100min

- Heating rate: 3.0℃/min

- Pressure: 3MPa

Measurement method

Undulation of prepreg after press (GEA-705G1010F78)

(Type F)

Conventional

Prepreg

| Item | Condition *3 | Unit | Actual Value | Test Method | ||

|---|---|---|---|---|---|---|

| GH-100 (Type DF) |

GH-200 (Type DF) |

(IPC-TM-650) | ||||

| Tg | TMA method | A | ℃ | 240–260 | 220–240 | 2.4.24.5 |

| DMA method | A | 240–260 | 250–270 | – | ||

| CTE *1 (Pull) | X (30–120℃) | A | ppm/℃ | 6–8 | 8–10 | 2.4.24.5 |

| Y (30–120℃) | 6–8 | 8–10 | ||||

| T260 (Without Copper) | A | min. | >60 | >60 | 2.4.24.1 | |

| T288 (Without Copper) | >60 | >60 | ||||

| Dielectric Constant *2 | 10GHz | A | – | 3.5–3.7 | 3.2–3.4 | IEC-62610 |

| Dissipation Factor *2 | 10GHz | A | – | 0.0025–0.0035 | 0.0020–0.0030 | |

*1) Heating Rate: 10℃/min., *2) Measured by cavity resonator method., *3) Refer to “Condition Note”

*Above data are experimental results and not guaranteed.

Standard Specifications

Prepreg

| Part Number | Type | Glass Cloth | Properties | |||

|---|---|---|---|---|---|---|

| Style | Resin Content (%) |

Dielectric Thickness after Lamination *1 (mm) |

||||

| GH-100 | (DF) | 0.025 | 1017F71K | 1017 | 71±2 | 0.027 |

| 1017F73K | 73±2 | 0.029 | ||||

| 1017F75K | 75±2 | 0.031 | ||||

| 1017F77K | 77±2 | 0.034 | ||||

| 1017F79K | 79±2 | 0.038 | ||||

| GH-200 | (DF) | 0.025 | 1017F68K | 1017 | 68±2 | 0.020 |

| 1017F70K | 70±2 | 0.022 | ||||

| 1017F72K | 72±2 | 0.024 | ||||

| 1017F74K | 74±2 | 0.026 | ||||

| 1017F76K | 76±2 | 0.028 | ||||

| 1017F78K | 78±2 | 0.031 | ||||

| 1017F80K | 80±2 | 0.034 | ||||

| 1017F82K | 82±2 | 0.038 | ||||

| 1017F84K | 84±2 | 0.043 | ||||

| Reference (IPC-TM-650) | 2.3.16 | ‐ | ||||

*1) The dielctric thickness after lamination is defined as the thickness of one sheet of prepreg when the resin flow is 0%.

This value changes depending on the press condition or inner layer pattern.