Base Materials for PWBs

Reduction of Solder Crack/Low Elastic Modulus Material – TD-002〈Prepreg〉

Product Information and Application

Product form

- Prepreg: TD-002

Applications

- Electronic equipment for automobiles.

- Engine room set board.

- PCB on component packagings.

Features

- Applied to PWB surface of standard material to absorb soldering stress and inhibit solder crack.

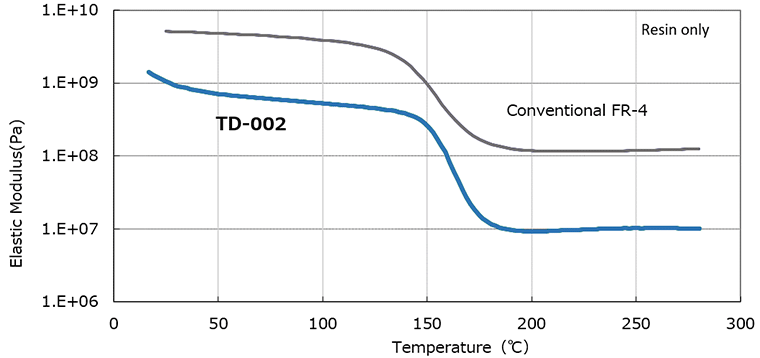

- Elastic modulus is 1/4 of that of standard FR-4.

- Enables to reduce solder crack without using high functional material by combining TD-002 with standard material.

Characteristics

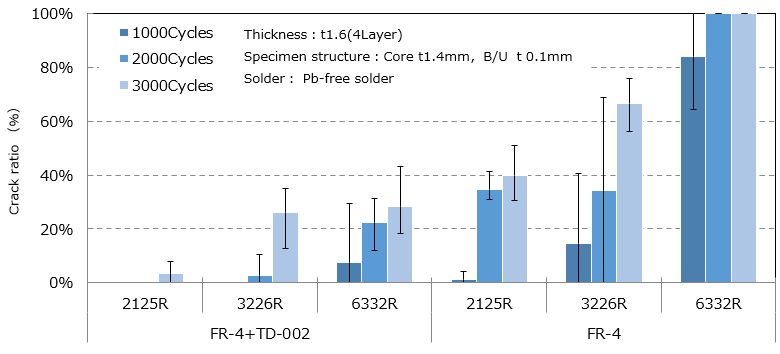

Connection reliability of Pb-free solder [Thermal condition: -40℃ (30min.)⇔125℃ (30min.)]

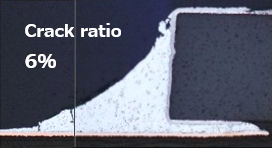

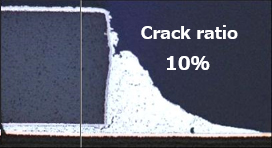

・Solder crack of TD-002+FR-4 (Cross section, after 3000cycles.)

2125R

3226R

Elastic Modulus

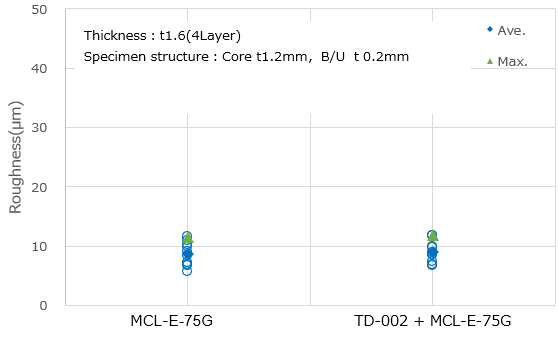

Mechanical drilling processing [After 3000 hits]

TD-002+MCL-E-75G

Appearance after drilling

Conditions of mechanical drilling

- Stack-up: 3 panels

- Revolution: 120 krpm

- Drill bit: φ 0.3 mm

- E/B: Al t0.15mm

- Feeding speed: 2.4m/min.

Prepreg

(3313N58, t0.4mm, t0.1mm)

| Item | Condition *3 | Unit | Actual Value | Reference (IPC-TM-650) |

||

|---|---|---|---|---|---|---|

| TD-002 | ||||||

| Tg | TMA method | A | ℃ | 155–170 | 2.4.24 | |

| CTE *1 | X (30–120℃) | A | ppm/℃ | 6–9 | ‐ | |

| Y (30–120℃) | 6–9 | |||||

| Z | (<Tg) | A | 80–130 | 2.4.24 | ||

| (>Tg) | A | 200–300 | ||||

| Solder Heat Resistance (260℃) | A | sec. | >300 | ‐ | ||

| T-260 (Without Copper) | A | min. | >50 | 2.4.24.1 | ||

| T-288 (Without Copper) | >5 | |||||

| Decomposition Temperature (TGA method 5% Weight Loss) | A | ℃ | 345–360 | 2.3.40 | ||

| Copper Peel Strength | 18 µm | A | kN/m | 0.8–0.9 | 2.4.8 | |

| 35 µm | 0.9–1.1 | |||||

| Flexural Modulus (Lengthwise) | A | GPa | 5–8 | 2.4.4 | ||

| Elastic Modulus (Lengthwise) Tensile | A | GPa | 7–10 | ‐ | ||

| Dielectric Constant | 1GHz *2 | A | - | 3.6–3.8 | IEC-62810 | |

| Dissipation Factor | 1GHz *2 | A | - | 0.011–0.013 | ||

| Volume Resistivity | C-96/40/90 | Ω・cm | 1×1014–1×1016 | 2.5.17 | ||

| Surface Resistance | C-96/40/90 | Ω | 1×1013–1×1015 | |||

| Insulation Resistance | A | Ω | 1×1014–1×1016 | ‐ | ||

| D-2/100 | 1×1012–1×1014 | |||||

*1) Heating Rate: 10℃/min., *2) Measured by cavity resonator., *3) Refer to “Condition Note”

*Above data are experimental results and not guaranteed.

Standard Specifications

Prepreg

| Part Number | Type | Glass Cloth | Properties | ||

|---|---|---|---|---|---|

| Style | Resin Content (%) |

Dielectric Thickness after Lamination *1 (mm) |

|||

| TD-002 | 0.06 | (1037N77) | 1037 | 77±2 | 0.069 |

| 0.08 | (1078N66) | 1078 | 66±2 | 0.088 | |

| 0.10 | (3313N58) | 3313 | 58±2 | 0.115 | |

| 0.20 | (1501N54) | 1501 | 54±2 | 0.208 | |

| Reference (IPC-TM-650) | 2.3.16 | ‐ | |||

*1) The dielectric thickness after lamination is defined as the thickness of one sheet of prepreg when the resin flow is 0%.

This value changes depending on the press condition or inner layer pattern.