High Heat Resistant Coating Materials

for Screen Printing

HP series is a high heat resistant paste with screen printable capability. It is used as junction coating resin for power devices and compliant layer for wafer level CSP. It is also suitable for non-contact high accuracy dispensing.

Features

The main feature of HP-500 is a polyimide series paste (varnish) with a particle-type soluble polyimide filler. While printing, the filler adds its thixotropic property to the paste, so that the printing process goes more smoothly. Then, after baking process, the filler dissolves in the base paste forming a uniform film. This is why the screened polyimide paste shows the excellent mechanical property and insulation.

Cross section of film

New

Conventional

Other Features

- Lactone type solvent is safe and used in our paste for low moisture absorption. Therefore, it shows excellent workability and stability.

- Excellent adhesion on silicon wafers and polyimide substrates.

- Possibility of non-contact coating by using a dispenser.

Applications

- Junction coating film for power devices

- Buffer coating film for semiconductor devices

- Stress buffer for wafer level CSP

- Protective film for electronic parts

Process

Screen printing process is an attractive way of simplifying semiconductor manufacturing process. It requires a mesh or metal screen. A screen printer aligns the screen in a substrate fixed on the table by air pressure, and then prints the screen pattern onto the substrate, applying paste with a brush. Mainly for this process, Hitachi Chemical has developed two new types of polyimide pastes. One of the type is “HP-500” series based on polyimide paste as heat-resistant paste with the printing function. The other type is “HP-200” series based on polyamideimide paste. These pastes are very useful for the development and design of advanced semiconductors.

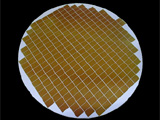

Application for WL-CSP

- It is an efficient way to use the paste, while spin-on coating process wastes large amount of the paste.

- Thick coating and fine patterns in large scale wafer (up to 300mm in diameter) can be obtained by single printing.

Characteristics (Typical Values)

| Item | Unit | HP-500 | HP-300 | HP-200 | Test method | |

|---|---|---|---|---|---|---|

| Features | — | Polyimide type High heat resistant High Insulation | Polyamideimide type “Low temp. film formation” | Polyamideimide type “Low temp. film formation” Low elastic modulus | — | |

| Paste properties | Solid content | % | 25 | 22 | 26 | — |

| Viscosity | Pa/s | 100 | 100 | 100 | E-type visometer | |

| Thixotropy | — | 3.6 | 3.2 | 3.2 | — | |

| Applicable film thickness | um | 5-20 | 5-20 | 40-50 | — | |

| Film properties | Tg | °C | 260 | 210 | 198 | TMA |

| Decomposition temp. | °C | 485 | 410 | 400 | TGA | |

| CTE | ppm/°C | 38 | 55 | 100 | TMA | |

| Elastic modulus | Gpa | 3.2 | 2.8 | 0.9 | DMA | |