Base Materials for PWBs

Halogen Free, High Tg, Low Transmission Loss, Low CTE Multilayer Material – MCL-HS200

Product Information and Application

Product form

- CCL: MCL-HS200

- Prepreg: GH-200

Applications

- Semiconductor packages. (FC-CSP, PoP, SiP)

- Thinner Module PWB

Features

- MCL-HS200 has hybrid properties of package and high speed materials.

- MCL-HS200 has low CTE value in X, Y directions and good dielectric property (Dk 3.7, Df 0.0040 at 10GHz).

- MCL-HS200(D) achieved low dielectric constant (3.4 at 10GHz) and low dissipation factor (0.0025 at 10GHz) using low Dk glass.

- Well-suited for build-up construction.

Characteristics

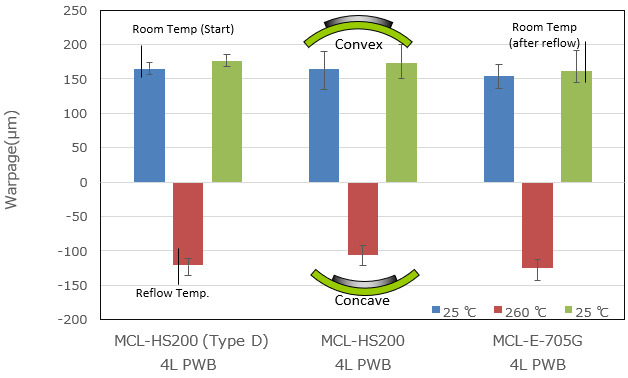

Warpage of 4 layer board

TEG Chip

- Chip size 10mm×10mm

- Chip thickness 100 µm

TEG Substrate

- Package size 14mm×14mm

- L1, 4: 12 µm Cu: 65%, L2, 3No Copper SR: 18 µm

- Core thickness: 45 µm

- Prepreg thickness: 45 µm

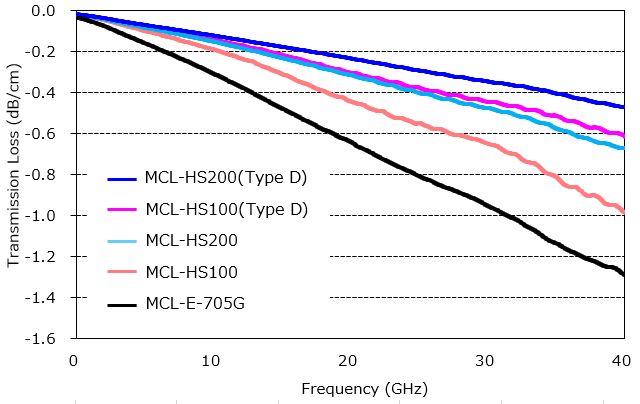

Transmission Loss

Measurement conditions

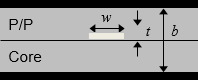

- Evaluation PWB: Strip-line

- Temperture and Humidity: 25℃/60%RH

- Characteristic impedance: Approx. 50Ω

- Proofreading method: TRL(Thru-Reflect-Line)

- Trace width(w): 0.12–0.14mm

- Dielectric thickness(b): 0.65mm

- Trace thickness(t): 18 µm

Thin Laminate

(t0.2, t0.4mm)

| Item | Condition *3 | Unit | Actual Value | Reference (IPC-TM-650) |

|||

|---|---|---|---|---|---|---|---|

| MCL-HS200 | MCL-HS200 (Type D) | ||||||

| Tg | TMA method | A | ℃ | 220–240 | 2.2.24 | ||

| DMA method | A | 250–270 | ‐ | ||||

| CTE *1 | X (30–120℃) | A | ppm/℃ | 8–10 | ‐ | ||

| Y (30–120℃) | A | 8–10 | |||||

| Z | <Tg | A | 25–35 | 2.2.24 | |||

| >Tg | 140–200 | ||||||

| Solder Heat Resistance (260℃) | A | sec. | >300 | ‐ | |||

| T-260 (Without copper) | A | min. | >60 | 2.4.24.1 | |||

| T-288 (Without copper) | A | >60 | |||||

| Decomposition Temperature (TGA method 5% weight loss) | A | ℃ | 410–430 | 2.3.40 | |||

| Copper Peel Strength | 12 µm | A | kN/m | 0.7–0.9 | 2.2.8 | ||

| 18 µm | A | 0.8–1.0 | |||||

| Surface Roughness (Ra) | A | µm | 2–3 | 2.2.17 | |||

| Flexural Modulus (Lengthwise) | A | GPa | 21–26 | 2.4.4 | |||

| Dielectric Constant | 10GHz *2 | A | ‐ | 3.6–3.8 | 3.2–3.4 | IEC-62810 | |

| Dissipation Factor | 10GHz *2 | A | ‐ | 0.0035–0.0045 | 0.0020–0.0030 | ||

| Volume Resistivity | C-96/20/65+C-96/40/90 | Ω・cm | 1×1014–1×1016 | 2.5.17 | |||

| Surface Resistance | C-96/20/65+C-96/40/90 | Ω | 1×1013–1×1015 | ||||

| Insulation Resistance | C-96/20/65 | Ω | 1×1014–1×1016 | ‐ | |||

| C-96/20/65+D-2/100 | 1×1013–1×1014 | ‐ | |||||

*1) Heating Rate: 10℃/min., *2) Measured by cavity resonator., *3) Refer to “Condition Note”

*Above data are experimental results and not guaranteed.

Standard Specifications

Copper Clad Laminate

| Part Number | Type | Copper Foil Thickness | Code Name | Laminate Thickness |

|---|---|---|---|---|

| MCL-HS200 | ‐ | 3,12, µm (LP, HVLP) |

U0.04 | 0.04mm |

| 3 µm 12 µm 18 µm (LP, RT, HVLP) |

M0.06 | 0.06mm | ||

| 0.1 | 0.10mm | |||

| 0.2 | 0.20mm | |||

| 0.41 | 0.41mm | |||

| (D) | 3,12, µm (LP, HVLP) |

DU0.04 | 0.04mm | |

| 3 µm 12 µm 18 µm (LP, RT, HVLP) |

DM0.06 | 0.06mm | ||

| D0.1 | 0.10mm | |||

| D0.2 | 0.20mm | |||

| D0.41 | 0.41mm |

Note1) Std: Standard copper foil, LP/HVLP: Low profile copper foil.

Note2) LP: 3 µm, 12 µm, HVLP: 12 µm, 18 µm.

Note3) The thickness means that of dielectric layer.

Prepreg

| Part Number | Type | Glass cloth | Properties | |||

|---|---|---|---|---|---|---|

| Style | Resin content (%) |

Dielectric Thickness after Lamination *1 (mm) |

||||

| GH-200 | (DF) | 0.025 | (See [GH-200 (Type DF)]page for ultra thin, flat prepregs) | |||

| ‐ | 0.03 | (1027N71) | 1027 | 71±2 | 0.039 | |

| 0.03 | (1027N77) | 1027 | 77±2 | 0.051 | ||

| 0.05 | (1037N73) | 1037 | 73±2 | 0.051 | ||

| 0.05 | (1037N77) | 1037 | 77±2 | 0.061 | ||

| 0.06 | (1078N63) | 1078 | 63±2 | 0.073 | ||

| 0.06 | (1078N73) | 1078 | 73±2 | 0.082 | ||

| 0.08 | (3313N60) | 3313 | 60±2 | 0.11 | ||

| (D) | 0.03 | (D1027N74) | 1027 | 74±2 | 0.041 | |

| 0.03 | (D1027N78) | 1027 | 78±2 | 0.049 | ||

| 0.05 | (D1035N69) | 1037 | 69±2 | 0.051 | ||

| 0.05 | (D1035N73) | 1037 | 73±2 | 0.059 | ||

| 0.06 | (D1078N65) | 1078 | 65±2 | 0.072 | ||

| 0.06 | (D1078N69) | 1078 | 69±2 | 0.083 | ||

| 0.08 | (D3313N62) | 3313 | 62±2 | 0.108 | ||

| Reference (IPC-TM-650) | 2.3.16 | ‐ | ||||

*1) The dielectric thickness after lamination is defined as the thickness of one sheet of prepreg when the resin flow is 0%.

This value changes depending on the press condition or inner layer pattern.