Base Materials for PWBs

Copper Foil for Fine Patterning – PF-EL

Product Information and Application

Product form

- Copper Foil: PF-EL

Applications

- Semiconductor package substrates

- High density multi-layer PWB

Features

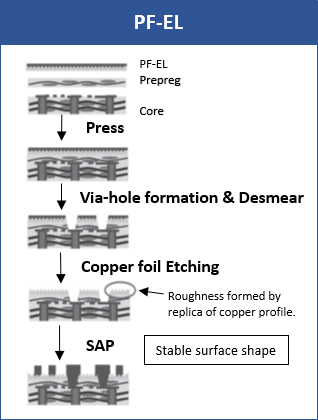

- PF-EL is a copper foil that is appropriate for fine line patterning with semi-additive process (SAP) using rough shapes of primer made with the copper profile.

- PF-EL has high peel strength for plating copper.

- High flexural modulus substrates with using prepregs.

Characteristics

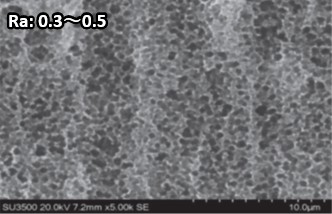

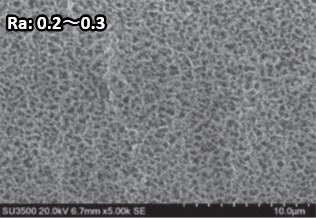

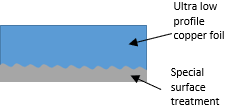

Surface

PF-EL

PF-EL SP

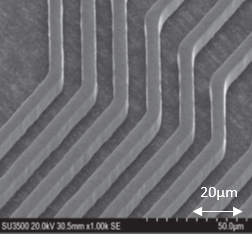

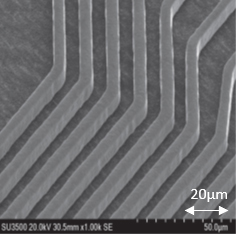

Fine patterning with SAP

Design

L/S=10/10 µm with PF-EL

(Exposure LDⅠ)

Design

L/S=7/7 µm with PF-EL SP

(Exposure LDⅠ)

Design

L/S=5/5 µm with PF-EL SP

(Exposure Stepper)

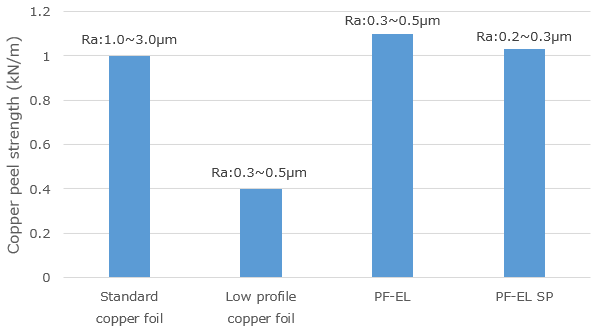

Copper peel strength

*Sample: MCL-E-770G (Type R), Copper foil 1.5 µm with plating copper 20 µm

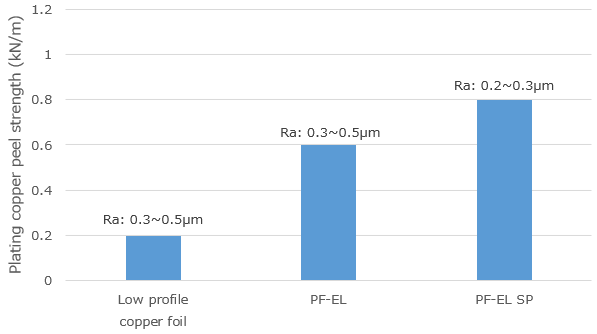

Plating copper peel strength

*Sample: MCL-E-770G (Type R), plating copper 20 µm

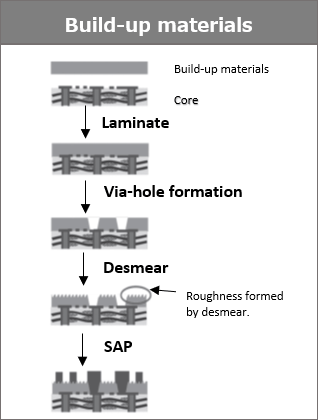

Fine patterning process

Standard Specifications

Copper Foil

| Part Number | Copper Foil Thickness (µm) |

Special Surface Treatment (µm) |

Roughness (µm) | Composition | Process |

|---|---|---|---|---|---|

| PF-EL-12 | 12 | 4 | Ra: 0.3–0.4 |  |

SAP *1 |

| Rz: 1.5–2.5 | |||||

| PF-EL-3 | 3 | 2, 4 | Ra: 0.3–0.5 | SAP *1 MSAP *2 |

|

| Rz: 1.5–2.5 | |||||

| PF-EL-2 | 2 | 2, 4 | Ra: 0.3–0.5 | ||

| Rz: 1.5–2.5 | |||||

| PF-EL-1.5 | 1.5 | 2 | Ra: 0.3–0.5 | ||

| Rz: 1.5–2.5 | |||||

| PF-EL-1.5SP | 1.5 | 2 | Ra: 0.2–0.3 | ||

| Rz: 1.0–2.0 |

*1) After lamination of the material to the prepreg, the copper foil is etched out,and the special surface treatment with appropriate roughness made by a replica of the copper profile etched out remains on prepreg surface.This process is SAP using this replica.

*2) Semi additive process using thin copper foil as seed layer for having E’less copper +copper on both patterming and via plating purpose.