Innovative Material Solutions

Resonac’s photosensitive interlayer insulation film PV-F, using photolithography, facilitates the formation of cavities 500μm square or larger. Filling these large cavities with copper plating enhances heat dissipation and conductivity, improving substrate design flexibility.

The need for machining difficult-to-work materials is boosting as fuel efficiency and electric mileage are to improve in automotive industry and increased demand for components in aircraft industry. In lathe machining, lathe speed is being increased to enhance productivity.

Wireless communications are advancing from 5G to 5G-Advanced and Beyond 5G (6G) in pursuit of higher speeds and larger capacity. To keep pace with these growing needs, smartphones and other mobile devices contain a burgeoning number of radio frequency (RF)…

The building industry aims to improve the thermal insulation property of glass windows in the pursuit of more energy-efficient buildings. With double-glazed glass in widespread use, vacuum insulated glass (VIG) is expected to become increasingly popular to meet the…

Highly efficient SiC (silicon carbide) power modules are becoming increasingly popular in electric vehicles (xEVs) for extending cruising range and improving fuel and electricity consumptions.

As the volume of information increases with the widespread use of the Internet of Things (IoT), 5G and other high-speed communication technologies, advanced driver-assistance systems (ADAS), and…

xEVs’ inverters are being improved to achieve higher output with a smaller and lighter system for the purpose of extending vehicles’ driving range while increasing their fuel efficiency or electric mileage.

Power semiconductors handling large currents and high voltages deliver excellent energy-saving performance, and are used in a wide range of applications that include home appliances, electric vehicles, industrial equipment, trains, solar cells, and communication base stations.

With Level 4 autonomous vehicles (fully autonomous driving without human assistance or intervention) coming into practical use, millimeter-wave radars as a method of sensing are being developed in the 77 GHz band (the 76 GHz and 79 GHz bands collectively.

Die bonding is the process of attaching a chip and substrate. In the past, Au-Si eutectic and soldering were common processing methods, but with the increasing variety of chips and the spread of copper lead frames, the internal stress caused by a mismatch between the…

Resonac’s Thermal Insulation Coating offers a porous structure with nanoscale pores (avg. 20 nm), smaller than the mean free path of air molecules (67 nm). With its high porosity (80-90%) and low solid density, the product achieves thermal conductivity of 0.03 W/(m・K).

Power semiconductors that control large currents or high voltage are increasingly used for their advanced energy saving performance in home appliances and electric vehicles as well as industrial machines, trains, solar batteries and telecommunication base stations…

“FANCRYL” <500 series> Series developed by Resonac has a bulky DCPD structure that it contributes to low cure shrinkage when added to 3D print resin formulations. These products improve the dimensional accuracy of 3D printed objects with fine, complicated shapes.

As the communications industry pursues higher speed and larger capacity from 5G to “5G-Advanced” to even “Beyond 5G (6G),” more and more attention is focused on higher frequency bands from millimeter to sub-terahertz waves.

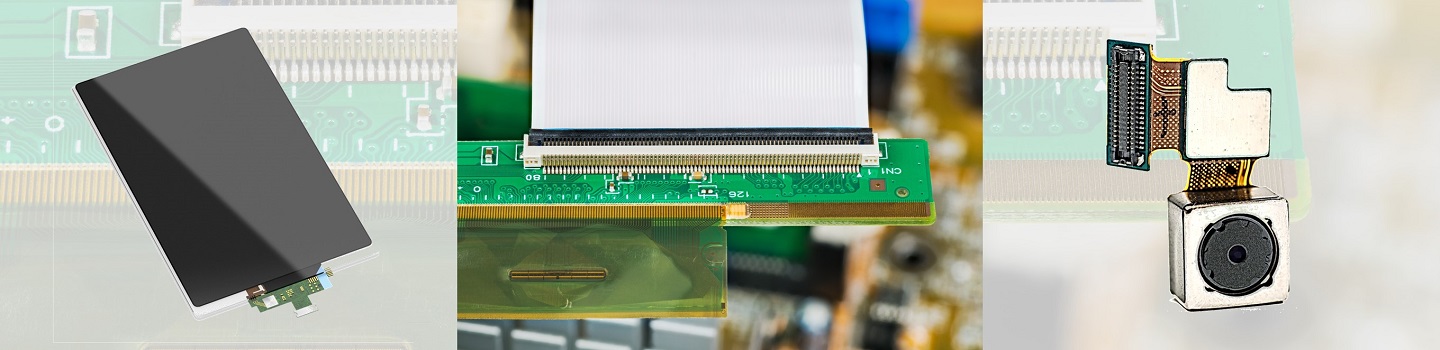

ACF is the initialism for “Anisotropic Conductive Film” or “Anisotropic Conductive Adhesive Film.” It is made of resins, such as thermoset epoxy resin, in which conductive particles are dispersed.

Our mold cleaning sheets in the <N-CS Series> are cleaning materials composed of thermosetting synthetic rubber. Because they are made of synthetic rubber, you can fill entire mold surfaces including cavities and parting surfaces with cleaning materials by placing sheets on a…

With the launch of 5th generation mobile communications systems (5G), the demand is growing for 5G compatible devices including smartphone incorporating millimeter-wave antenna modules.

As the volume of information increases with the spread of the Internet of Things (IoT), 5G and other high-speed communication technologies, advanced driver-assistance systems (ADAS), and generative artificial intelligence (AI), information processing devices for data centers and…

For NMP, which is generally used as a solvent for PAI, there is a concern about reproductive toxicity, and NMP is handled as a restricted substance under the REACH regulations.

Our PCB stress absorption prepreg <TD-002> with low elastic modulus absorbs stress in solder joints and reduces cracks if it is used on the outside layers of the PCB stackup, contributing to higher reliability of on-board communication module.

“PNVA” is the water-soluble polymer produced by polymerization of N-vinylacetamide. Resonac only succeeded in the commercial production.

Our isotropic conductive film allows for bonding using a vacuum laminator under a temperature of around 100ºC and a pressure of 0.1 MPa.

Our Mold Cleaning Sheets in the are cleaning materials composed of thermosetting synthetic rubber. The cleaning agent contained in the sheets permeates and dissolves stains, and the adhesive force of the synthetic rubber removes the stain components.

Our lithium-ion battery binder uses polyamide-imide resin which forms strong coating films with the elastic modulus of 2.5 GPa or over and tensile strength of 100 MPa or over.

When our <PR2500> is used as an additive for butyl rubber, the tensile strength after heat treatment (thermal aging resistance test at 177ºC for 96 hours) is approx. 2.7 times that of the butyl rubber in which sulfur is used.